The forethought of interior design work and woodwork brings to us the cloddish image of raw edges, fear of scratching the skin or ruining a lovely dress and the bare edges mocking the elegance of our dream home. But we need not be agitated by the clumsiness of our carpenter as the edge bands have emerged as the epitome of serenity in the furniture design.

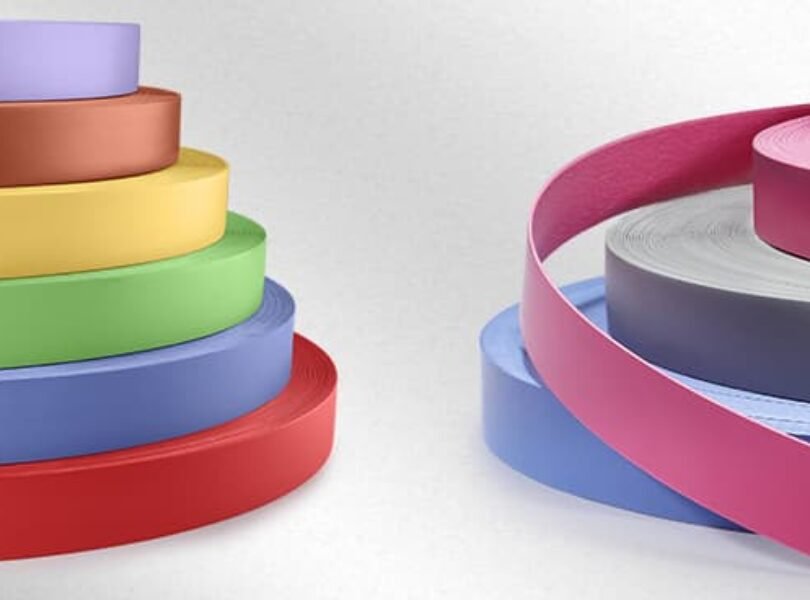

While the process of adorning and dressing up of raw and erratically grained edges of wood using strips of materials such as PVC, ABS, acrylic, melamine, and wood or wood veneer is referred to as edge banding, the thin strip itself is called edge band. Based on material composition edge bands are classified as under

PVC Edge bands: Polyvinyl chloride is a plastic-based material with enhanced durability and excellent processing characteristics. The PVC edge bands apart from the ability to be manufactured in the desired colour, texture and design, possess a brilliant trait of safety against fire and chemicals used in cleaning agents. Due to their innumerable qualities, it is the most sought after material in edge band manufacturing.

ABS Edge bands: Acrylonitrile butadiene styrene has many similarities with PVC but its lower density and lack of fire resistance defeat its popularity against PVC edge bands.

Polypropylene (PP) Edge bands: It is semi-crystalline plastic with excellent suitability for radial applications. It is sometimes used as an alternative to PVC and ABS edge bands.

PMMA Edge bands: These are made of state-of-the-art thermoplastic material and the transparency and lustre of acrylic are better than glass thereby making it preferable for giving glossy edges to furniture.

Wood Veneer Edge bands: These are made by joining individual pieces of wood to form a continuous roll. The variety of wood used for this purpose includes mahogany, maple, oak and walnut. But they suffer from similar drawbacks, like any other wood article, and are getting redundant with the presence of better options in the form of PVC Edge bands.

Each of the aforementioned categories of edge bands has its benefits and utilities, and they satisfy their specific intended purpose. Of all the types of edge bands discussed above the PVC edge bands get an edge in selection by the designers and workmen as they are impermeable, so next time your child playfully spills that bottle of water on your favourite tabletop, don’t forget to thank the edge band imparting the subtle protection to your wood. Another fascinating benefit associated with PVC edge bands is its heterogeneity in shades and colours. Moreover, they can be custom-made to suit customer demands and they are best suited for purposes involving curved surfaces, unlike its wooden counterpart.

For each laminate produced in the industry, one can find a complementing Richies edge band as their focus on industrial innovation pivoted on the satisfaction of customer’s requirements has led them to be ready with a plethora of exactly matching options for your taste of furniture laminate as well as wood.