Understanding the Different Materials Used in Edge Banding Tape Manufacturing

Ever wonder what gives furniture that smooth finish? Edge banding is an important element in designing furniture. It gives aesthetical value and the durability of furniture. A piece of furniture without this may even lose its sense of style and practical use.

But why is this tape so important, and why should it matter to you? Whether you’re seasoned or new to furniture making, knowing the materials in an edge banding tape could change everything about how you approach your projects. Let’s explore this amazing world of edge banding together!

Why Edge Banding Tape is Important for Furniture Design?

You knew that open edges on furniture are not just ugly but also prone to damage? Edge banding tape guards surfaces against chipping, moisture, and wear and tear of daily life.

Beyond protection, it elevates a piece’s design by creating a polished, seamless finish. Think about it: would you prefer a jagged edge or a smooth, professional look? That’s the kind of transformation edge banding brings. Plus, it makes maintenance a breeze—smooth edges repel dust and grime better than rough cuts.

Benefits of using Edge Banding Tape for Furniture Production

Let’s admit it: nobody wants high-maintenance furniture or furniture prone to wear. Edge banding tape solves both these issues:

- Better Durability: Sealing raw edges gives furniture protection against moisture, scratches, and wear, keeping it longer.

- Better Appearance: A clean edge doesn’t just serve a practical purpose; it’s fashion-forward, making ordinary furniture into pieces of art.

- Streamlined Production: It provides streamlined production, its ease in application allows conserving time on assembly.

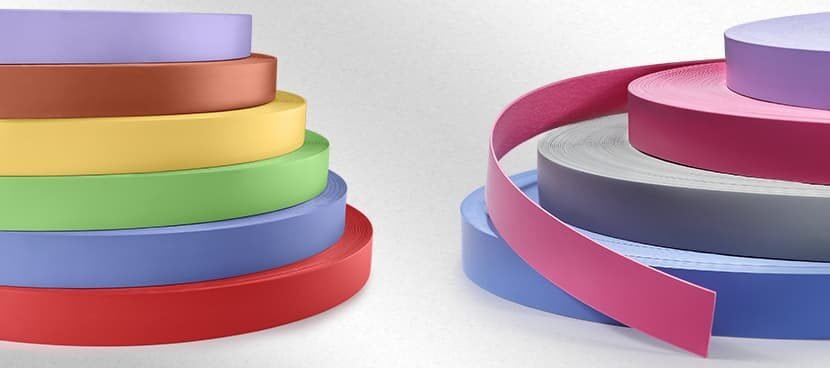

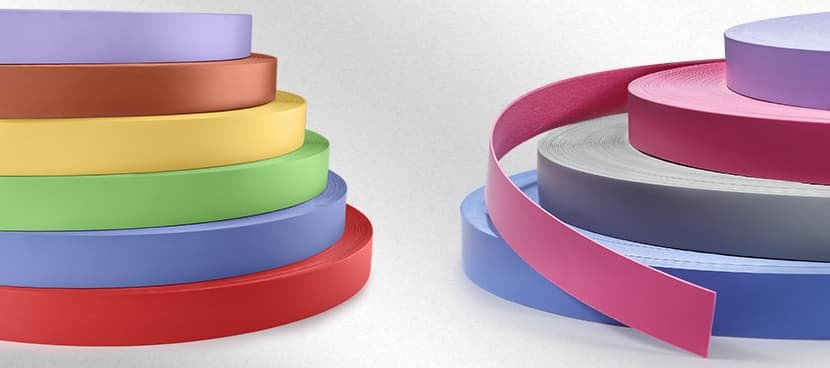

- Design Flexibility: Edges banding tape does the amazing thing about design versatility-the endless choice of colours as well as textures gives you options with which to create unusual but of-trend designs.

So, when you just wanted a look that sounded overly lavish but at a premium finish without a premium tag-and-edge banding tape to the rescue.

Common Materials Used in Edge Banding Tape Manufacturing

Are you wondering which material is best for your furniture needs? Here’s a breakdown of popular edge banding tape materials:

- PVC (Polyvinyl Chloride): Durable, water-resistant, and inexpensive—ideal for kitchen furniture.

- ABS (Acrylonitrile Butadiene Styrene): This one has good strength and fine finishing and is recommended for those impact points.

- Wood Veneer: Natural and elegant, it’s the go-to for creating a warm, authentic look.

- Melamine: Scratch-resistant and versatile, melamine offers a wide range of colors for creative designs.

- Polyester: Vibrant and glossy, it’s great for contemporary styles that demand visual appeal.

- Acrylic: Want a high-gloss, modern finish? Acrylic provides stunning transparency and durability.

Factors to Consider When Choosing Edge Banding Tape Material

Have you ever chosen a material, only to realize later that it wasn’t the right fit? Here’s how to avoid that mistake:

- Aesthetics: Think about how the tape will blend with your furniture’s design. Do you want a bold contrast or a subtle match?

- Durability: For high-traffic areas, opt for resilient materials like ABS or PVC.

- Adhesive Compatibility: Should be smooth with your desired substrates.

- Budget: Be able to balance between cost and quality for an almost premium yet practical result.

- Installation: Certain materials require specialized equipment, so make sure to have those in mind.

Eco-Friendly Edge Banding Tape Options

Time to get greener with your furniture designs? With growing options, the demand for eco-friendly edge banding tape solutions that will not compromise on quality is becoming higher.

- Bamboo Veneer: Fast-growing and carbon-absorbing, bamboo tops the charts when talking about the green-friendly look.

- Recycled PVC: The perfect blend of strength with low environmental impact since existing plastics are reused.

- Natural Fibers: Minimal processing, but maximum sustainability: Jute and hemp have these two as their greatest features.

- Biodegradable adhesives: They take less time to degrade thus reduce landfill waste.

Maintenance Tips for Various Edge Banding Tape Materials

Want your edge banding tape looking sharp? Here’s the way to do it:

- PVC: Wipe with a damp cloth containing mild soap. Avoid scrubbing cleaners to avoid scratching.

- ABS: Regular dusting and gentle cleaning can keep it looking new.

- Wood Veneer: Wipe with a microfiber cloth and avoid excess moisture from making it warp.

- Melamine: Standard household cleaners are good for it, but always test them first.

- Polyester/Acrylic: Manufacturer recommended solvents can be used for tougher stains.

Conclusion: Choosing the Right Projects for You

Edge banding tape selection goes beyond mere functionality-it’s more about style, strength, and sustainability in your furniture. Whether you choose budget-friendly PVC, natural wood veneer, or the environment-friendly bamboo, there’s a perfect fit for each of your projects.

Take a moment to explore your options, consider your needs, and let Edgebands enhance your furniture designs. Remember that those small details, such as edge banding tape, can make a difference for standout furniture.